-

rhode alain,FranceIt is very nice to work with real professionals. They are attentive and responsive.

rhode alain,FranceIt is very nice to work with real professionals. They are attentive and responsive. -

Alejandro Gidi,Mexicoexcellent communication from seller. Ms Daisy was clear and on time, product was shipped properly packaged. A+

Alejandro Gidi,Mexicoexcellent communication from seller. Ms Daisy was clear and on time, product was shipped properly packaged. A+ -

Sergey Shapotkin,Russian Federeverything fine

Sergey Shapotkin,Russian Federeverything fine

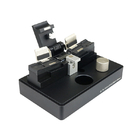

Large Diameter Single Fiber Mechanical Aligners Temporary Joining Tools for Cladding Diameter 250μm & 400μm Fibers

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Applicable Fiber | Silica Glass Optical Fiber (SM & MM) | Fiber Count | Single Fiber |

|---|---|---|---|

| Cladding Diameter | 250μm Or 400μm | Cleave Length | 13mm |

| Insertion Loss | 0.03dB (Typ.), 0.1dB (Max.) @ Telecom Wavelength | Operating Temperature | -10 To +40 ℃ |

| Dimensions (W X D X H) | 120(W) X 75(D)x 60(H) Mm | Weight | 480 G (not Including Fiber Holders) |

Large Diameter Single Fiber Mechanical Aligners

Temporary Joining Tools

Precision & Durable

Description

The LDMA-250-CSF & LDMA-400-CSF are temporary mechanical fiber splices for fiber and cable connections to test equipment or devices such as optical passive components (FBT Splitter, Circulator, Isolator, Collimator & Filter, etc.), OTDRs or fiber optic cable reels. They use precision ceramic V-groove to align 250μm & 400μm cladding single fiber. The fibers are prepared for joining by using our large diameter fiber preparation tools (thermal strippers, cleaning tools, and fiber cleavers). Using the LDMA in conjunction with an Optical Meter equipped with an optical pigtail provides rapid one-button optical tests and no need to fusion splice for saving money and time.

Features

- Factory, Labs & Field serviceable

- Precision ceramic V-groove alignment*

- Rotating knob & Magnetic lids intensive press operation for more precision alignment

- Plastic screw to prevent damage from knob rotating in delivery

*Custom V-groove Size Available.

Specifications

| Model No. | LDMA-250-CSF | LDMA-250-CSF |

| Applicable Fiber | silica glass optical fiber (SM & MM) | |

| Fiber Count | Single fiber | |

| Cladding Diameter | 250μm | 400μm |

| Cleave Length | 13mm | |

| Insertion Loss1 | 0.03dB (Typ.), 0.1dB (Max.) @ Telecom Wavelength | |

| Operating Temperature | -10 to +40 ℃ | |

| Dimensions (W x D x H) | 120(W) x 75(D)x 60(H) mm | |

| Weight | 480 g (not including fiber holders) | |

Note: 1. Under the condition of proper fiber preparation, and attenuation is specified for unterminated fiber

Operations

1. Fiber preparation:

Use a larger diameter fiber thermal stripper to peel off the coating layer of the fiber about 40mm, wipe off the dirt on the bare fiber with an alcohol cotton ball, and put the single fiber into the fiber holder of a large diameter fiber cleaver.

cut the fiber, and leave the bare fiber about 13mm long. Put the prepared fiber into the fiber holder of LDMA.

2. Place the optical fiber:

Open the lids, take off the plastic screw, and rotate the knob to move the right holding block to the furthest position. Put the fiber holder on the right holding block (prepared bare fiber into the V-shaped groove simultaneously), dip a small amount of matching liquid into the V-shaped groove, the same operation to the right holding block and fiber holder on it, then put down the pressure plate, rotate the knob to make sure that the two optical fibers are in contact, meanwhile, check the parameters on the tester.

3. Notes:

Do not hit or scrape the precision V-shaped groove with hard objects, so as not to damage the groove body and affect the connection accuracy. You must wipe off the dirt in the V-shaped groove with an alcohol cotton ball every time you use it.

4. Cleaning tips:

Because the matching gel becomes viscous after long-term use, the knob turns not smoothly enough. We can solve that by soaking the whole machine in pure water for one hour, then rinsing and wiping the machine clean.

Order Information

| Model No. | Description |

| LDMA-250-CSF |

1 PCS Large Diameter Single Fiber Mechanical Aligner/Temporary Joining Tool (Magnetic Lids) 1 PCS 10ml Refractive Index Matching Liquid 1 Pair Fiber Holders for 400μm Buffer Coating (One Left & One Right) * 1 PCS User Manual |

| LDMA-400-CSF |

1 PCS Large Diameter Single Fiber Mechanical Aligner/Temporary Joining Tool (Magnetic Lids) 1 PCS 10ml Refractive Index Matching Liquid 1 Pair Fiber Holders for 550μm Buffer Coating (One Left & One Right) * 1 PCS User Manual |

| (Large Diameter Fiber preparation tools are available) |

*Custom Fiber Holder Diameter Available.