-

rhode alain,FranceIt is very nice to work with real professionals. They are attentive and responsive.

rhode alain,FranceIt is very nice to work with real professionals. They are attentive and responsive. -

Alejandro Gidi,Mexicoexcellent communication from seller. Ms Daisy was clear and on time, product was shipped properly packaged. A+

Alejandro Gidi,Mexicoexcellent communication from seller. Ms Daisy was clear and on time, product was shipped properly packaged. A+ -

Sergey Shapotkin,Russian Federeverything fine

Sergey Shapotkin,Russian Federeverything fine

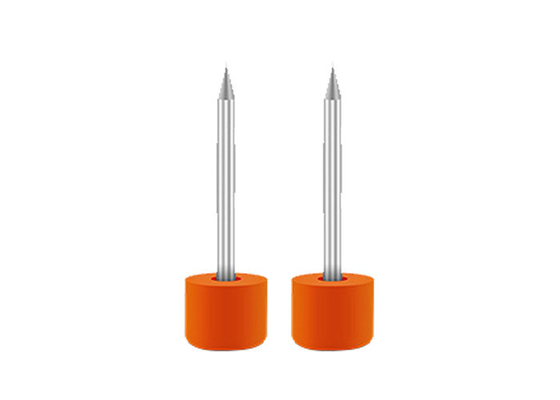

Tungsten Steel 2mm Fiber Optic Sumitomo Electrodes

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Fiber Optic Fusion Splicer Replacement Electrode | Electrode Lifetime | 3000-5000 Times |

|---|---|---|---|

| Diameter | 2mm | Warranty | 1 Year |

| Material | Tungsten Steel | Packing | 1pair/box |

| Highlight | Fiber Optic Sumitomo Electrodes,2mm Sumitomo Electrodes,tungsten steel Sumitomo Electrodes |

||

Fiber Optic Sumitomo Electrodes Type-35 Type-36 Type-39 Fiber Optic Fusion Splicer Electrodes

Description:

Imported high-quality tungsten steel, stable discharge, low loss, long life, precision machining

Complete models, quality assurance, stable discharge, connect at least 40,000 cores

The imported tungsten steel electrode is magnified 400 times under the microscope, the tip of the electrode is still sharp, the surface is clean and smooth, which ensures the stability of discharge, low loss and long service life.

Under the microscope of ordinary material electrode, the electrode tip becomes blunt after 400 times magnification, the surface is rough, causing discharge deviation, large loss and easy damage to the welding machine.

![]()

![]()

Feature:

1. Imported tungsten steel material uses 93A fine grain tungsten steel

2. Stable discharge, low loss, can be used for trunk welding

3. Excellent quality, precise craftsmanship, precise processing size

4.Durable fixing cap The fixing cap is made of insulating material, resistant to high temperature and no deformation

5. Protective sleeve protection The outside of the rod body is protected by a protective sleeve to avoid abrasion when it is not used.

Imported tungsten steel electrode or common material electrode

![]() or

or![]()

Specification:

| Product name | fiber optic fusion splicer electrode |

| Application: | Customers request |

| Life: | 4000times |

| Unit | 1pair |

| Material: | Imported Tungsten Steel |

| Weight | 6g |

| Advantage: | long-last lifespan |

| Color: | black silver |

How to replace the electrode?

First, make sure that the fusion splicer is off, remove the protective cover of the electrode chamber, loosen the screws that fix the upper electrode, take out the electrode, and then loosen the top wire of the lower electrode to take out the electrode. Secondly, install a new electrode, the operation steps are opposite to the method of disassembling the electrode, just operate in sequence. The gap between the two electrode tips is required to be; 2.6 plus or minus 0.2 mm. Finally, during the assembly process, do not touch the electrode tip to prevent damage to the electrode and prevent the electrode from falling into the machine and causing damage. After replacing the electrode, the arc position should be calibrated.

Electrode cleaning and arc calibration

1. After the electrode is installed, turn on the power switch of the fusion splicer.

2. After the splicer enters the initial screen, press the menu button to enter the first level menu.

3. Find the machine maintenance by moving the cursor, enter the cleaning electrode item, after confirmation, the machine will automatically discharge to clean and age the electrode.

4. Install the cut left and right fibers, find the arc position item by moving the cursor, and keep the fiber end face and the two electrode tips at three points and one line through the operation, the machine will conduct a discharge test, and adjust it according to the actual situation.

5. Finally, press the menu button to exit in turn.